PUT SOME SNAP IN YOUR CUSTOMERS’ PRINTED JOBS

they will love it!

Today’s printer faces increasing demand for vibrant, clean, sharp 4-color printing. It is now possible for you to meet your customers’ needs with The SNAP SET Web Drying System. This unique, compact system utilizes infrared lights to allow for drying of ink on coated and uncoated paper.

The Snap Set Web Drying Technology is an innovative breakthrough for coldset printing. It produces a quality, eye-catching heatset product with no fluting for a fraction of the cost of traditional heatset printing equipment. In addition, it offers a significantly lower capital investment, significantly lower operating costs, smaller space requirements and reduced environmental issues.

The Snap Set system is a flexible system. You can switch from coldset to heatset runs by simply changing the paper stock and engaging the dryer system. The end result is bold, vibrant printing with no fluting, lower costs and significantly less downtime.

Uniquely adapted to coldset web offset press equipment, this system is driven by exclusive software that controls all functional aspects of operation. With the application of infrared lights, blowers and chill rollers, marking and offsetting are eliminated on all paper types.

Importantly, the print quality and color vibrancy of all your web products, coated and uncoated, will be significantly improved.

The Snap Set Solution

Application

Information Reporting

Application

The traditional coldset web printer will capture a new segment of the market by competing for those customers demanding a glossy heatset product for a fraction of the capital cost and operating costs of traditional heatset systems. The Snap Set Web Drying System allows coldset printers to produce gloss products and wood ground products on the same press equipment with switching out ink or making time-consuming press adjustments.

Description

Information Reporting

Application

The Snap Set solution is an electric, compact drying system that incorporates heat-generating infrared lights, blowers, control pad, software, chill roll system and casing housing. The components are configured to allow heatset ink drying on coated and non-coated roll paper stocks at speeds up to 45,000 impressions per hour.

The system is uniquely suited for coldset web offset press equipment.

Information Reporting

Information Reporting

Information Reporting

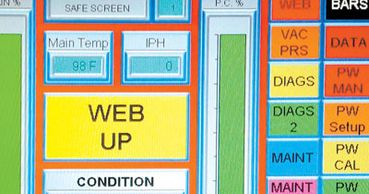

The Snap Set stem is driven by software. The touch screen control pad is integrated into all functions of the system and provides data rich reporting that can be accessed remotely.

The safe screen is the system “home” screen which provides a system safe condition. The web screen is the system operation screen used while running the infrared. These first two screen are

the ones that will be used most often by operators.

System Components

Infrared Lights Housing Unit

Infrared Lights Housing Unit

Infrared Lights Housing Unit

Long-lasting infrared lights, encased in a steel housing unit provide intense heat to dry the ink. The system includes fresh air and exhaust blowers attached to motor-driven chill rollers. The heat and chillers can be adjusted for press speed and drying temperature.

Chiller and Water Reservoir

Infrared Lights Housing Unit

Infrared Lights Housing Unit

The system maintains chill roller water and a lower, constant temperature. Additionally, the unit conserves space and energy.

Air Blower Chiller

Infrared Preheat Device

Infrared Preheat Device

Blowers and chillers are combined in a proprietary technology to eliminate fluting, scratching and marking on the finished printed product.

Infrared Preheat Device

Infrared Preheat Device

Infrared Preheat Device

The system preheats the sheet and reduces moisture content. The software and keypad allow for monitoring press settings to control temperature and press speed.

Snap Set Web Dryers

Copyright © 2023 Snap Set Web Dryers - All Rights Reserved.

Powered by GoDaddy